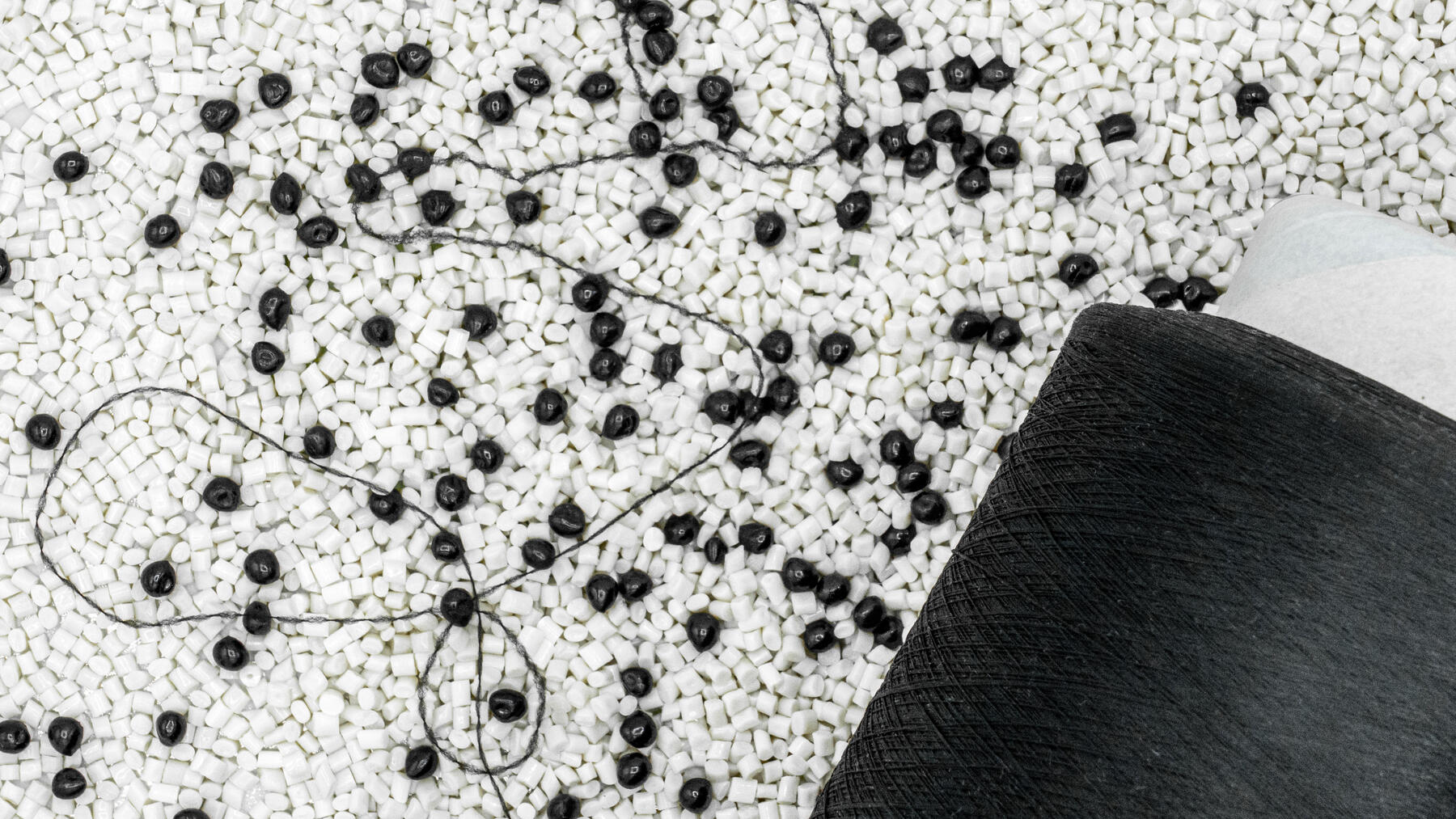

Recycled polyester:

bottle in a fabric

How does it work?

The plastic bottles are cleaned and shredded into flakes. These are then poured and melted, turning into a paste. The paste is transformed into filament thanks to an extrusion screw. This filament is then spun around a reel, creating the recycled polyester thread!

Why this choice?

Using recycled polyester filaments enables us to reduce the CO2 emissions linked to the production of the yarn by at least 17% compared to using virgin polyester.